Enhancing Quality,

Reducing Waste & Costs

Enhancing Quality,

Reducing Waste & Costs

Enhancing Quality,

Reducing Waste & Costs

Enhancing Quality,

Reducing Waste & Costs

Up to 99% precision in pharmaceutical visual inspection, lowering costs, reducing waste, improving efficiency & patient safety.

Up to 99% precision in pharmaceutical visual inspection, lowering costs, reducing waste, improving efficiency & patient safety.

Up to 99% precision in pharmaceutical visual inspection, lowering costs, reducing waste, improving efficiency & patient safety.

Up to 99% precision in pharmaceutical visual inspection, lowering costs, reducing waste, improving efficiency & patient safety.

Note: Due to compliance and data protection policies, the designs on my case study have been modified *. To learn more about the product, visit the website.

Note: Due to compliance and data protection policies, the designs on my case study have been modified *.

To learn more about the product, visit the website.

Beyond Labeling: The Bigger Picture

Beyond Labeling: The Bigger Picture

Beyond Labeling: The Bigger Picture

This case study showcases only a small part (Labelling app) of a much larger solution. Achieving high-quality results required collaboration between data scientists, project managers, product owner, engineers, UI/UX designer and domain experts to ensure accuracy at scale. The SaaS solution includes data dashboard, AI model performance analytics, image library, managing application, labelling application, heat maps and much more. Labeling is a crucial step in building reliable training datasets—poor labels lead to ineffective models, limiting inspection performance and increasing costs. To solve this, we designed a tailor-made labeling app that supports labelers in making precise, scalable decisions—ensuring defect-free drug production, AI-driven efficiency, and cost savings.

This case study showcases only a small part (Labelling app) of a much larger solution. Achieving high-quality results required collaboration between data scientists, project managers, product owner, engineers, UI/UX designer and domain experts to ensure accuracy at scale. The SaaS solution includes data dashboard, AI model performance analytics, image library, managing application, labelling application, heat maps and much more. Labeling is a crucial step in building reliable training datasets—poor labels lead to ineffective models, limiting inspection performance and increasing costs. To solve this, we designed a tailor-made labeling app that supports labelers in making precise, scalable decisions—ensuring defect-free drug production, AI-driven efficiency, and cost savings.

Final design*

Final design*

Final design*

Design Principals Applied

Visibility & Feedback

Visibility & Feedback

Visibility & Feedback

Task progress indicator

Clear status indicators for defect detection

Task progress indicator

Clear status indicators for defect detection

Task progress indicator

Clear status indicators for defect detection

Accessibility & Equity

Accessibility & Equity

Accessibility & Equity

Efficiency & Workflow

Efficiency & Workflow

Efficiency & Workflow

Use shortcuts

Predictive inputs to improve speed.

Use shortcuts

Predictive inputs to improve speed.

Use shortcuts

Predictive inputs to improve speed.

*High-Fidelity Prototype – Due to compliance and data protection policies, these visuals and data have been modified for showcasing purposes.

*High-Fidelity Prototype – Due to compliance and data protection policies, these visuals and data have been modified for showcasing purposes.

Project Goal

Project Goal

Project Goal

Designing a labeling system to…

Designing a labeling system to…

Designing a labeling system to…

Accuracy

Accuracy

Accuracy

Enhance quality control by minimizing human error, reducing user fatigue, and improving inspection reliability with AI.

Enhance quality control by minimizing human error, reducing user fatigue, and improving inspection reliability with AI.

Enhance quality control by minimizing human error, reducing user fatigue, and improving inspection reliability with AI.

Safety

Safety

Safety

Enhance defect verification to prevent potential vial content contamination, consequently, minimize patient risk.

Enhance defect verification to prevent potential vial content contamination, consequently, minimize patient risk.

Enhance defect verification to prevent potential vial content contamination, consequently, minimize patient risk.

Simplification

Simplification

Simplification

Reduce the number of images labelers need to analyze by improving AI accuracy and automating repetitive tasks.

Reduce the number of images labelers need to analyze by improving AI accuracy and automating repetitive tasks.

Reduce the number of images labelers need to analyze by improving AI accuracy and automating repetitive tasks.

Waste Reduction

Waste Reduction

Waste Reduction

Improve defect classification through better AI training, minimizing false rejections, reducing waste, and enhancing sustainability

Improve defect classification through better AI training, minimizing false rejections, reducing waste, and enhancing sustainability

Improve defect classification through better AI training, minimizing false rejections, reducing waste, and enhancing sustainability

Research

Research

Research

Problem

Pharmaceutical manufacturers face challenges with visual inspection accuracy

Pharmaceutical manufacturers face challenges with visual inspection accuracy

In the pharmaceutical industry, automated inspection machines with multiple camera stations often misidentify defects, causing two issues:

False Positives: Good products are wrongly ejected, wasting resources.

False Negatives: Defects go undetected, risking safety.

To address this, human inspectors double-check ejected products. However, they often miss micro-defects, making the process unreliable and leading to waste, higher costs, and safety concerns.

In the pharmaceutical industry, automated inspection machines with multiple camera stations often misidentify defects, causing two issues:

False Positives: Good products are wrongly ejected, wasting resources.

False Negatives: Defects go undetected, risking safety.

To address this, human inspectors double-check ejected products. However, they often miss micro-defects, making the process unreliable and leading to waste, higher costs, and safety concerns.

Challenges

Reducing repetitive workload for labelers.

Detecting micro-defects invisible to the human eye.

Improving the precision and consistency of defect labeling to train AI systems.

Reducing repetitive workload for labelers.

Detecting micro-defects invisible to the human eye.

Improving the precision and consistency of defect labeling to train AI systems.

Project overview

Duration: 6 months

Year: 2024

Role: UI/UX

Tools: Figma, Miro, Jira, Confluence

Status: Released

My key responsibilities

Conducting user research

Wireframe and prototyping

A/B and moderated testing

Ensuring compliance and accuracy in the interface.

Team

Stakeholders

Project managers

Product owner

Data scientist

Software engineers

QA | Quality Assurance

User Insights

User Insights

User Insights

To understand user pain points and needs, I conducted an affinity mapping session, grouping insights into four key themes: Human Factors & Cognitive Load, Safety & Compliance, Efficiency, Sustainability and Waste Reduction. Based on these insights, a persona was created to guide design decisions.

To understand user pain points and needs, I conducted an affinity mapping session, grouping insights into four key themes: Human Factors & Cognitive Load, Safety & Compliance, Efficiency, Sustainability and Waste Reduction. Based on these insights, a persona was created to guide design decisions.

Key Insights

01

01

01

Accuracy Challenges

Accuracy Challenges

Accuracy Challenges

Fatigue from high-volume labeling reduces precision, increasing errors and inconsistencies in AI training.

Fatigue from high-volume labeling reduces precision, increasing errors and inconsistencies in AI training.

Fatigue from high-volume labeling reduces precision, increasing errors and inconsistencies in AI training.

02

02

02

Safety & Compliance Risks

Safety & Compliance Risks

Safety & Compliance Risks

Inconsistent defect labeling affects verification, increasing compliance risks and potential safety concerns.

Inconsistent defect labeling affects verification, increasing compliance risks and potential safety concerns.

Inconsistent defect labeling affects verification, increasing compliance risks and potential safety concerns.

03

03

03

Repetitive Workload

Repetitive Workload

Repetitive Workload

Labelers repeatedly classify the same defect types, making the process time-consuming.

Labelers repeatedly classify the same defect types, making the process time-consuming.

Labelers repeatedly classify the same defect types, making the process time-consuming.

04

04

04

Sustainability Concerns

Sustainability Concerns

Sustainability Concerns

High false rejection rates result in unnecessary waste and increased production costs.

High false rejection rates result in unnecessary waste and increased production costs.

High false rejection rates result in unnecessary waste and increased production costs.

Solution definition

Solution definition

Solution definition

Devices

For detailed tasks like defect labeling (zoom, drag, bounding boxes), screen size is critical for usability and accuracy.

For detailed tasks like defect labeling (zoom, drag, bounding boxes), screen size is critical for usability and accuracy.

For detailed tasks like defect labeling (zoom, drag, bounding boxes), screen size is critical for usability and accuracy.

Monitors / Laptops

Monitors / Laptops

Monitors / Laptops

Offer ample space for labeling and multitasking,

with ergonomic setups reducing user strain.

Min. screen size: 13 inches

Offer ample space for labeling and multitasking, with ergonomic setups reducing user strain.

Min. screen size: 13 inches

Offer ample space for labeling and multitasking,

with ergonomic setups reducing user strain.

Min. screen size: 13 inches

Tablet

Tablet

Tablet

Lightweight and portable, ideal for on-the-go work or travel.

Requirement: Stylus/pen for improved accuracy.

Min. screen size: 10.5 inches

Lightweight and portable, ideal for on-the-go work or travel.

Requirement: Stylus/pen for improved accuracy.

Min. screen size: 10.5 inches

Lightweight and portable, ideal for on-the-go work or travel.

Requirement: Stylus/pen for improved accuracy.

Min. screen size: 10.5 inches

Proposed Features

Enhanced Labeling Tools

Enhanced Labeling Tools

Enhanced Labeling Tools

Track progress

Zoom and drag for detailed inspection.

Guideline defects library

Bounding box functionality to highlight defects manually and automatically.

Consistency Checks

Consistency Checks

Consistency Checks

Assigning the same set of images to multiple labels (manager task).

Generating a consistency report with precision scores for each labeler.

Audit trail log

AI-Assisted Labeling

AI-Assisted Labeling

AI-Assisted Labeling

Suggested defect labels with color-coded frames for quick verification.

Editable suggestions to ensure user control.

Design, Iteration & Usability Testing

Design, Iteration & Usability Testing

Design, Iteration & Usability Testing

To assess the prototype's usability and uncover potential pain points, users completed tasks simulating real-world interactions. These tasks targeted key functionalities to ensure the design enhances efficiency, accuracy, and ease of use. This testing phase is crucial in identifying and addressing issues early, preventing costly mistakes in the final design. For feature testing, I prefer using a mid-fidelity prototype over a low-fidelity one, as it provides clearer visual and interactive cues. This helps users better understand their tasks and actions, leading to more accurate and meaningful feedback.

To assess the prototype's usability and uncover potential pain points, users completed tasks simulating real-world interactions. These tasks targeted key functionalities to ensure the design enhances efficiency, accuracy, and ease of use. This testing phase is crucial in identifying and addressing issues early, preventing costly mistakes in the final design. For feature testing, I prefer using a mid-fidelity prototype over a low-fidelity one, as it provides clearer visual and interactive cues. This helps users better understand their tasks and actions, leading to more accurate and meaningful feedback.

To assess the prototype's usability and uncover potential pain points, users completed tasks simulating real-world interactions. These tasks targeted key functionalities to ensure the design enhances efficiency, accuracy, and ease of use. This testing phase is crucial in identifying and addressing issues early, preventing costly mistakes in the final design. For feature testing, I prefer using a mid-fidelity prototype over a low-fidelity one, as it provides clearer visual and interactive cues. This helps users better understand their tasks and actions, leading to more accurate and meaningful feedback.

Test Insights & Design Improvements

Problem

Users struggle to differentiate between defects and selections, leading to confusion and potential errors

Users experienced frustration due to the inability to revise previous labels, increasing the risk of errors.

If an image has a selection but no actual defect, manually marking 'No Defect' each time becomes tedious and inefficient

Added a 'Previous' option, allowing users to revisit and adjust the last three given labels, and a 'Next' option to return to the desired image

Add a "No Defect" button to mark all selections in the image at once, reducing manual effort.

Design solution

Use distinct colors to differentiate defects from selections, ensuring clarity. Make defects stand out over the image by applying a semi-transparent overlay

Problem

Users struggle to differentiate between defects and selections, leading to confusion and potential errors

Users experienced frustration due to the inability to revise previous labels, increasing the risk of errors.

If an image has a selection but no actual defect, manually marking 'No Defect' each time becomes tedious and inefficient

Added a 'Previous' option, allowing users to revisit and adjust the last three given labels, and a 'Next' option to return to the desired image

Add a "No Defect" button to mark all selections in the image at once, reducing manual effort.

Design solution

Use distinct colors to differentiate defects from selections, ensuring clarity. Make defects stand out over the image by applying a semi-transparent overlay

Problem

Users struggle to differentiate between defects and selections, leading to confusion and potential errors

Users experienced frustration due to the inability to revise previous labels, increasing the risk of errors.

If an image has a selection but no actual defect, manually marking 'No Defect' each time becomes tedious and inefficient

Added a 'Previous' option, allowing users to revisit and adjust the last three given labels, and a 'Next' option to return to the desired image

Add a "No Defect" button to mark all selections in the image at once, reducing manual effort.

Design solution

Use distinct colors to differentiate defects from selections, ensuring clarity. Make defects stand out over the image by applying a semi-transparent overlay

Problem

Users struggle to differentiate between defects and selections, leading to confusion and potential errors

Users experienced frustration due to the inability to revise previous labels, increasing the risk of errors.

If an image has a selection but no actual defect, manually marking 'No Defect' each time becomes tedious and inefficient

Added a 'Previous' option, allowing users to revisit and adjust the last three given labels, and a 'Next' option to return to the desired image

Add a "No Defect" button to mark all selections in the image at once, reducing manual effort.

Design solution

Use distinct colors to differentiate defects from selections, ensuring clarity. Make defects stand out over the image by applying a semi-transparent overlay

*Mid-Fidelity Mockup – Due to compliance and data protection policies, these visuals and data have been modified for showcasing purposes.

*Mid-Fidelity Mockup – Due to compliance and data protection policies, these visuals and data have been modified for showcasing purposes.

*Mid-Fidelity Mockup – Due to compliance and data protection policies, these visuals and data have been modified for showcasing purposes.

KPI's

Defect detection accuracy: 99% of defects are now detected by the AI system, compared to manual inspections or legacy machine systems

Task completion time: Reduced by 75%, from 4 minutes to 1 minute per image labeling task after UI an AI improvements (considering the product first version).

User satisfaction: 90% of labelers reported increased satisfaction with the new interface, rating it 4 or higher out of 5.

Lessons Learned

Lessons Learned

Lessons Learned

Key Takeaways

User wellness is the key

User wellness is the key

User wellness is the key

User fatigue directly impacts labeling accuracy and consistency.

User fatigue directly impacts labeling accuracy and consistency.

User fatigue directly impacts labeling accuracy and consistency.

Intuitive Enhancements

Intuitive Enhancements

Intuitive Enhancements

Intuitive design features and AI suggestions can significantly enhance productivity.

Intuitive design features and AI suggestions can significantly enhance productivity.

Intuitive design features and AI suggestions can significantly enhance productivity.

Clear Status Indicators

Clear Status Indicators

Clear Status Indicators

Visual feedback and status indicators are essential for tracking defect detection progress and ensuring user confidence

Visual feedback and status indicators are essential for tracking defect detection progress and ensuring user confidence

Visual feedback and status indicators are essential for tracking defect detection progress and ensuring user confidence

Reflection

This project reinforced the importance of user-centered design in high-stakes industries like pharmaceuticals. By addressing usability challenges such as error correction, visibility, and workflow efficiency, the design ensures a smoother and more accurate defect detection process.

Additionally, incorporating customization options (e.g., light/dark mode, adjustable contrast) highlights the need for accessibility and adaptability in professional tools. The insights gained from usability testing were instrumental in refining the design, proving that small, intuitive enhancements can make a significant impact on user productivity and accuracy.

Moving forward, continuous feedback and iteration will be key to further optimizing the user experience and ensuring that technology supports, rather than hinders, critical decision-making.

This project reinforced the importance of user-centered design in high-stakes industries like pharmaceuticals. By addressing usability challenges such as error correction, visibility, and workflow efficiency, the design ensures a smoother and more accurate defect detection process.

Additionally, incorporating customization options (e.g., light/dark mode, adjustable contrast) highlights the need for accessibility and adaptability in professional tools. The insights gained from usability testing were instrumental in refining the design, proving that small, intuitive enhancements can make a significant impact on user productivity and accuracy.

Moving forward, continuous feedback and iteration will be key to further optimizing the user experience and ensuring that technology supports, rather than hinders, critical decision-making.

This project reinforced the importance of user-centered design in high-stakes industries like pharmaceuticals. By addressing usability challenges such as error correction, visibility, and workflow efficiency, the design ensures a smoother and more accurate defect detection process.

Additionally, incorporating customization options (e.g., light/dark mode, adjustable contrast) highlights the need for accessibility and adaptability in professional tools. The insights gained from usability testing were instrumental in refining the design, proving that small, intuitive enhancements can make a significant impact on user productivity and accuracy.

Moving forward, continuous feedback and iteration will be key to further optimizing the user experience and ensuring that technology supports, rather than hinders, critical decision-making.

Next steps

Leverage these learnings to design scalable, inclusive solutions for other high-compliance industries while continuing to prioritize sustainability and usability.

Leverage these learnings to design scalable, inclusive solutions for other high-compliance industries while continuing to prioritize sustainability and usability.

Leverage these learnings to design scalable, inclusive solutions for other high-compliance industries while continuing to prioritize sustainability and usability.

Portfolio

See other projects

See other projects

Bite - Frozen meal

E-commerce ∙ Case study

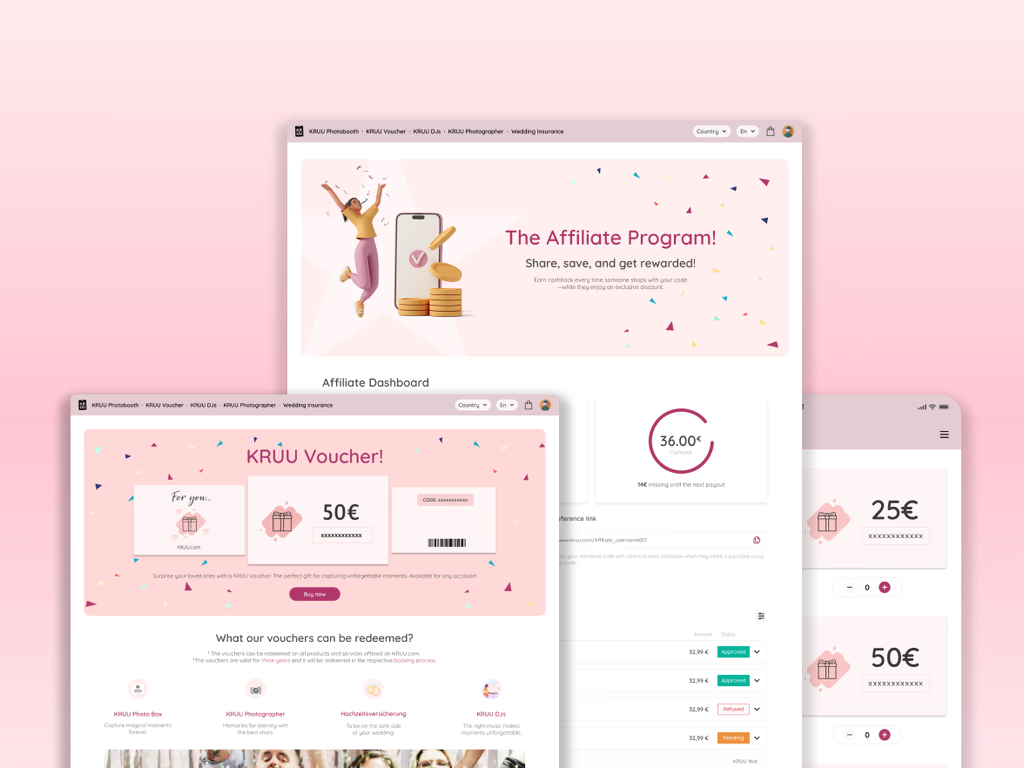

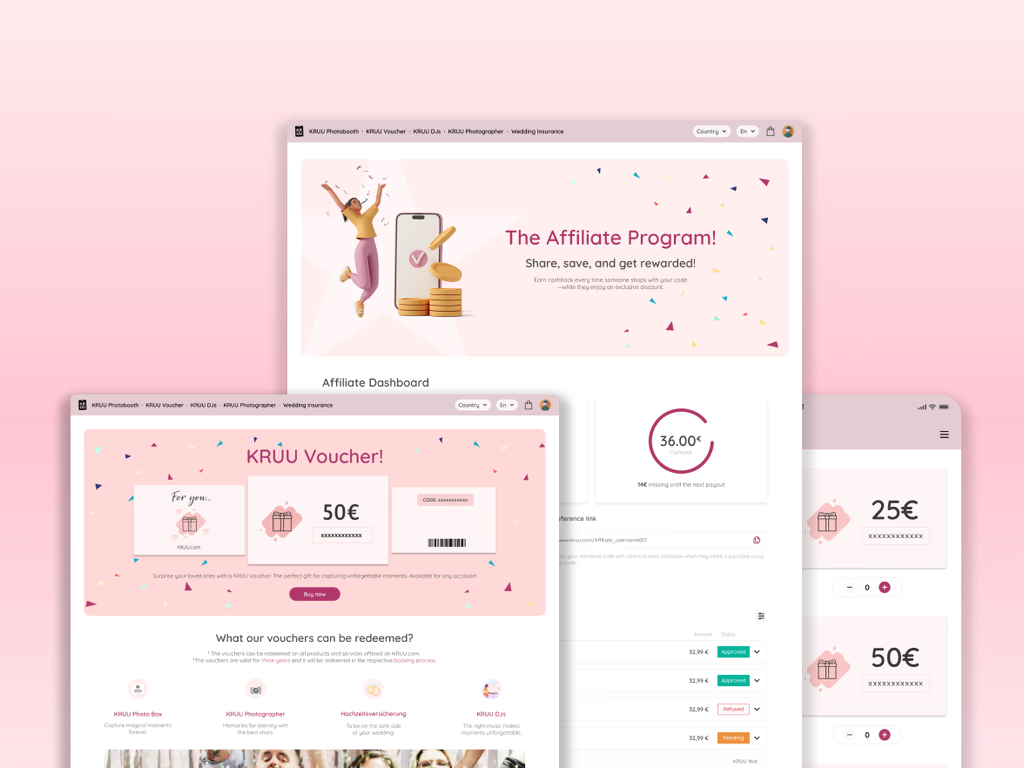

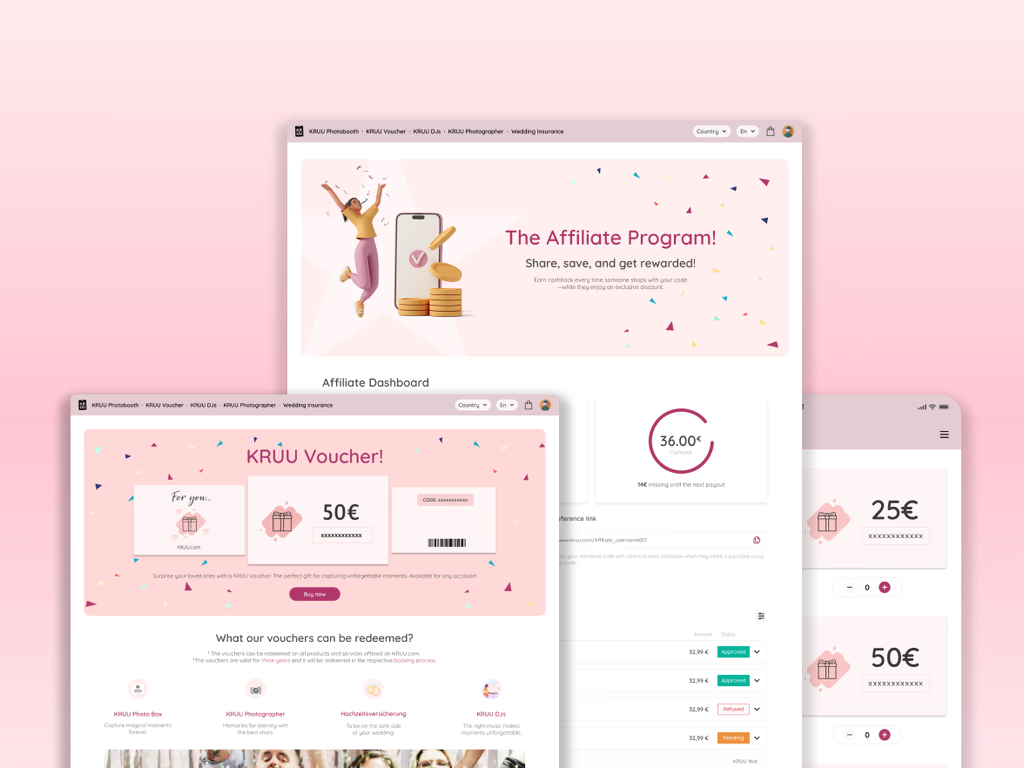

KRUU Premium events

E-commerce ∙ Events ∙ UI

AOP The punk rock band

E-commerce ∙ Events ∙ UI