Enhancing Quality,

Reducing Waste & Costs

Enhancing Quality,

Reducing Waste & Costs

Enhancing Quality,

Reducing Waste & Costs

Enhancing Quality,

Reducing Waste & Costs

Up to 99% precision in pharmaceutical visual inspection, lowering costs, reducing waste, improving efficiency & patient safety.

Up to 99% precision in pharmaceutical visual inspection, lowering costs, reducing waste, improving efficiency & patient safety.

Up to 99% precision in pharmaceutical visual inspection, lowering costs, reducing waste, improving efficiency & patient safety.

Up to 99% precision in pharmaceutical visual inspection, lowering costs, reducing waste, improving efficiency & patient safety.

Professional Project

99% Defect detection accuracy

The AI system identifies nearly all defects, outperforming both manual/ machine inspections

75% Faster task completion

From 4 min to under 1 min per image labeling task after UI an AI improvements

100% User satisfaction

Visual inspectors reported increased satisfaction with the new interface

Note: Due to compliance and data protection policies, some designs and data have been modified*. This case study showcases only a small part of the project, highlighting one of its many features and ecossystem. To learn more about the product, visit the website here.

Note: Due to compliance and data protection policies, some designs and data have been modified*. This case study showcases only a small part of the project, highlighting one of its many features and ecossystem. To learn more about the product, visit the website here.

Note: Due to compliance and data protection policies, some designs and data have been modified*. This case study showcases only a small part of the project, highlighting one of its many features and ecossystem. To learn more about the product, visit the website here.

Context

1% error rate can cost €50M. Automated inspection machines in pharma often misidentify defects, leading to wasted resources (false positives) and safety risks (false negatives). Human visual double-checks are unreliable, increasing costs and compliance risks. To address these issues, Körber pharma applies AI to automate visual inspection, accurately detecting defects in vials and ampules.

1% error rate can cost €50M. Automated inspection machines in pharma often misidentify defects, leading to wasted resources (false positives) and safety risks (false negatives). Human visual double-checks are unreliable, increasing costs and compliance risks. To address these issues, Körber pharma applies AI to automate visual inspection, accurately detecting defects in vials and ampules.

Project Overview

As the UI/UX designer, between 2021-2024, I led the end-to-end design of a SaaS platform for pharmaceutical quality control, collaborating with stakeholders, engineers, data scientists, product owners, project managers, and users. This case study focuses on the Labeling app—a key part of this ecosystem—designed to improve labeling accuracy, efficiency, and user experience in a high-compliance environment.

As the UI/UX designer, between 2021-2024, I led the end-to-end design of a SaaS platform for pharmaceutical quality control, collaborating with stakeholders, engineers, data scientists, product owners, project managers, and users. This case study focuses on the Labeling app—a key part of this ecosystem—designed to improve labeling accuracy, efficiency, and user experience in a high-compliance environment.

1

1

1

1

Discovery/Research

Discovery/Research

Discovery/Research

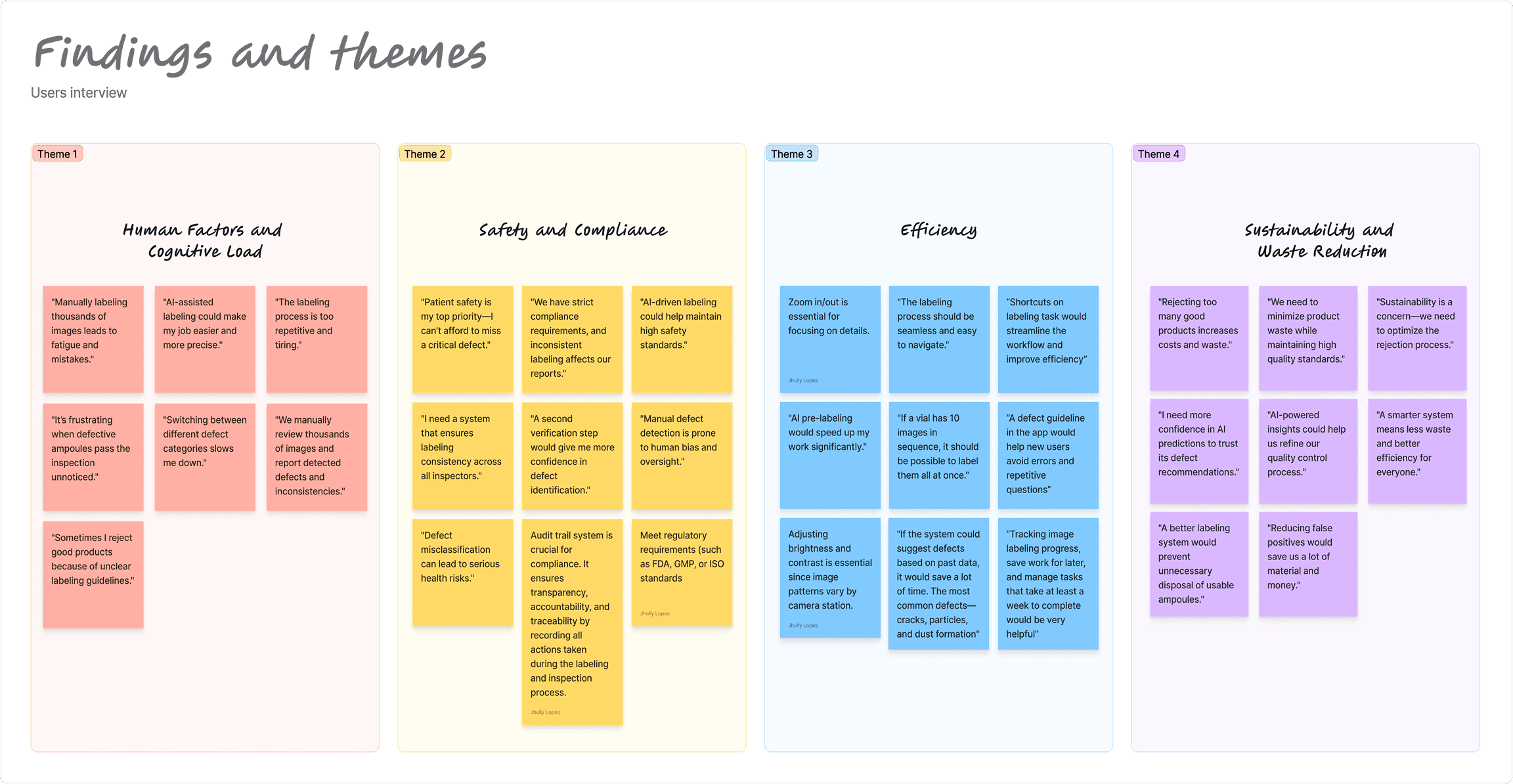

To understand the real challenges in pharmaceutical visual inspection, I conducted qualitative research with 6 end users, combining user interviews, workflow analysis, and stakeholder workshops. Using affinity mapping, I grouped insights into four key themes: Human Factors & Cognitive Load, Safety & Compliance, Efficiency, and Sustainability & Waste Reduction. These findings revealed user pain points and business needs, and helped align expectations across teams. Based on these insights, I created a persona to guide design decisions.

To understand the real challenges in pharmaceutical visual inspection, I conducted qualitative research with 6 end users, combining user interviews, workflow analysis, and stakeholder workshops. Using affinity mapping, I grouped insights into four key themes: Human Factors & Cognitive Load, Safety & Compliance, Efficiency, and Sustainability & Waste Reduction. These findings revealed user pain points and business needs, and helped align expectations across teams. Based on these insights, I created a persona to guide design decisions.

To understand the real challenges in pharmaceutical visual inspection, I conducted qualitative research with 6 end users, combining user interviews, workflow analysis, and stakeholder workshops. Using affinity mapping, I grouped insights into four key themes: Human Factors & Cognitive Load, Safety & Compliance, Efficiency, and Sustainability & Waste Reduction. These findings revealed user pain points and business needs, and helped align expectations across teams. Based on these insights, I created a persona to guide design decisions.

Key Insights

Key Insights

Key Insights

User pain points

❌ High cognitive load and fatigue from repetitive labeling tasks

❌ Difficulty distinguishing subtle defects

❌ Frustration with lack of feedback

Business impact

❌ Increased operational costs due to high false reject rates

❌ Delays in production and quality assurance

❌ Compliance risks and potential threats to patient safety

2

2

2

2

Define

Define

Define

After gathering insights from users and stakeholders during the research phase, I synthesized the findings to clearly define the core problem and project objectives. This stage focused on translating user pain points and business needs into actionable goals, setting a clear direction for the design process.

After gathering insights from users and stakeholders during the research phase, I synthesized the findings to clearly define the core problem and project objectives. This stage focused on translating user pain points and business needs into actionable goals, setting a clear direction for the design process.

After gathering insights from users and stakeholders during the research phase, I synthesized the findings to clearly define the core problem and project objectives. This stage focused on translating user pain points and business needs into actionable goals, setting a clear direction for the design process.

Challenges

Repetitive tasks and fatigue lead to errors

AI struggles with subtle defect classification

Onboarding new operators is slow and costly

Repetitive tasks and fatigue lead to errors

AI struggles with subtle defect classification

Onboarding new operators is slow and costly

Problem Statement

Problem Statement

Problem Statement

Manual visual inspection in pharmaceutical quality control is prone to human error, fatigue, and inconsistency—leading to unreliable defect detection, increased costs, and potential safety risks.

Manual visual inspection in pharmaceutical quality control is prone to human error, fatigue, and inconsistency—leading to unreliable defect detection, increased costs, and potential safety risks.

Manual visual inspection in pharmaceutical quality control is prone to human error, fatigue, and inconsistency—leading to unreliable defect detection, increased costs, and potential safety risks.

Project Goal

Project Goal

Project Goal

Accuracy

Accuracy

Accuracy

Minimize human error in defect labeling

Minimize human error in defect labeling

Minimize human error in defect labeling

Safety

Safety

Safety

Improve reliability and consistency of inspections

Improve reliability and consistency of inspections

Improve reliability and consistency of inspections

Simplification

Simplification

Simplification

Reduce user fatigue during inspection tasks

Reduce user fatigue during inspection tasks

Reduce user fatigue during inspection tasks

Waste Reduction

Waste Reduction

Waste Reduction

Support sustainability by reducing waste and operational costs

Support sustainability by reducing waste and operational costs

Support sustainability by reducing waste and operational costs

Solution definition

Solution definition

Solution definition

Devices

For detailed tasks like defect labeling (zoom, drag, bounding boxes), screen size is critical for usability and accuracy.

For detailed tasks like defect labeling (zoom, drag, bounding boxes), screen size is critical for usability and accuracy.

For detailed tasks like defect labeling (zoom, drag, bounding boxes), screen size is critical for usability and accuracy.

Monitors / Laptops

Designed for efficient multitasking and labeling, with ergonomic setups to reduce strain. Recommended for stationary work environments. Minimum screen size: 13 inches.

Tablet

Lightweight and portable, ideal for mobile or travel use. Requires a stylus or pen for precise input. Minimum screen size: 10.5 inches.

Proposed Features

Enhanced Labeling Tools

Enhanced Labeling Tools

Enhanced Labeling Tools

Track progress

Zoom and drag

Bounding box

Consistency Checks

Consistency Checks

Consistency Checks

Precision scores report

Audit trail log

Precision scores report

Audit trail log

AI-Assisted Labeling

AI-Assisted Labeling

AI-Assisted Labeling

AI suggestions

Editable by user

3

3

3

3

Ideation & Solution Exploration

Ideation & Solution Exploration

Ideation & Solution Exploration

During the ideation phase, the Product Owner was closely involved in shaping and validating our assumptions. Together, we defined key hypotheses to guide design decisions and prioritize features for testing.

During the ideation phase, the Product Owner was closely involved in shaping and validating our assumptions. Together, we defined key hypotheses to guide design decisions and prioritize features for testing.

During the ideation phase, the Product Owner was closely involved in shaping and validating our assumptions. Together, we defined key hypotheses to guide design decisions and prioritize features for testing.

Hypotheses

Hypotheses

Hypotheses

If we provide real-time feedback on labeling progress, users will feel more motivated and engaged

Streamlining the labeling workflow will reduce cognitive load and improve overall task efficiency

Offering a comprehensive defect library will help users make more consistent labeling decisions

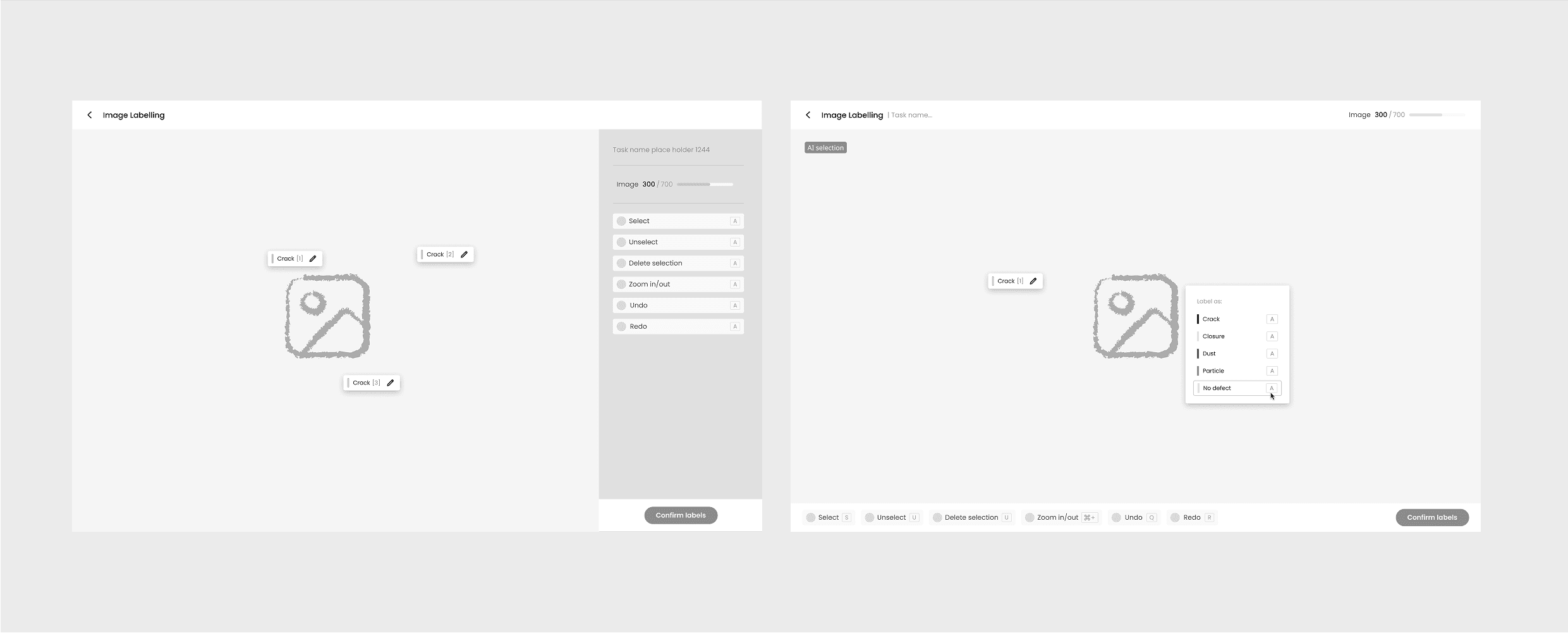

First Drafts

First Drafts

First Drafts

4

4

4

4

Validation & Refinement

Validation & Refinement

Validation & Refinement

I led refinement workshops with the full team to gather input and address technical challenges. This collaborative approach ensured the design was feasible and aligned with both user needs and technical constraints. To validate usability and identify pain points, users tested key features through real-world tasks using a mid-fidelity prototype. At least 3 iterations were conducted based on feedback, refining the design and preventing costly issues later.

I led refinement workshops with the full team to gather input and address technical challenges. This collaborative approach ensured the design was feasible and aligned with both user needs and technical constraints. To validate usability and identify pain points, users tested key features through real-world tasks using a mid-fidelity prototype. At least 3 iterations were conducted based on feedback, refining the design and preventing costly issues later.

I led refinement workshops with the full team to gather input and address technical challenges. This collaborative approach ensured the design was feasible and aligned with both user needs and technical constraints. To validate usability and identify pain points, users tested key features through real-world tasks using a mid-fidelity prototype. At least 3 iterations were conducted based on feedback, refining the design and preventing costly issues later.

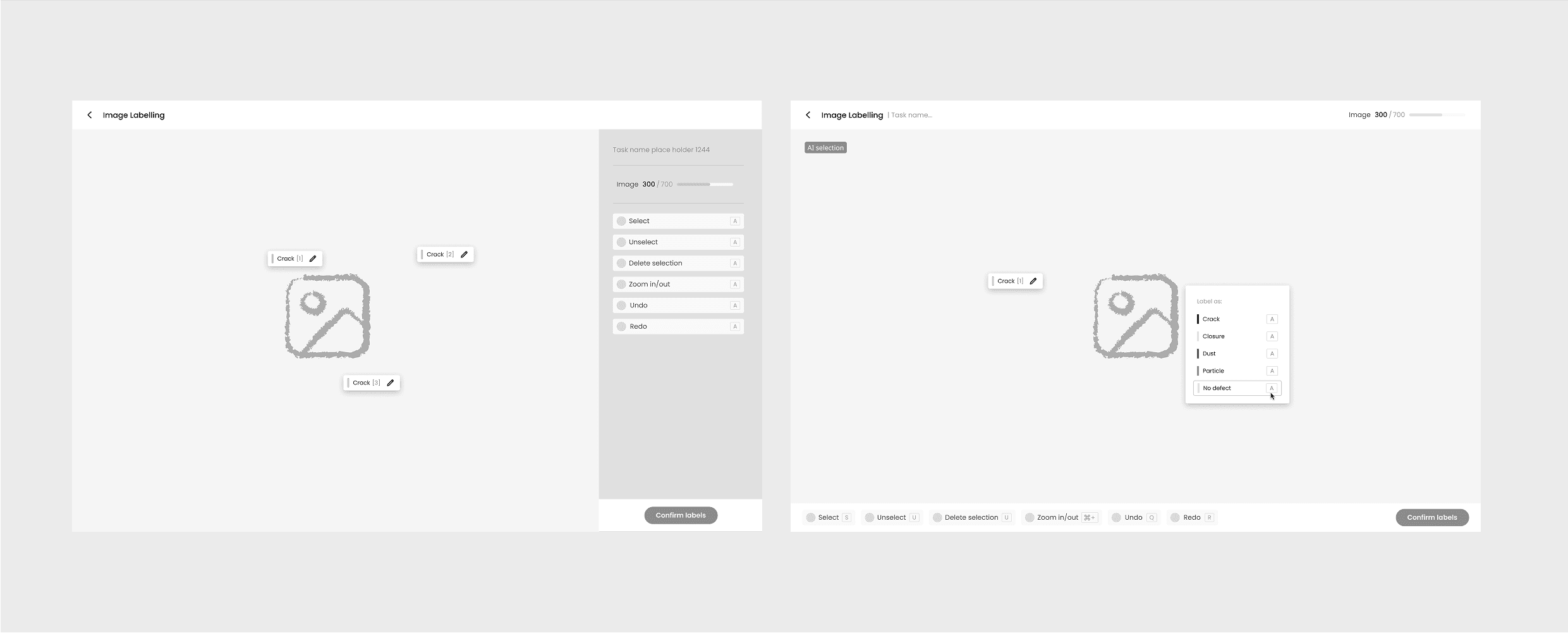

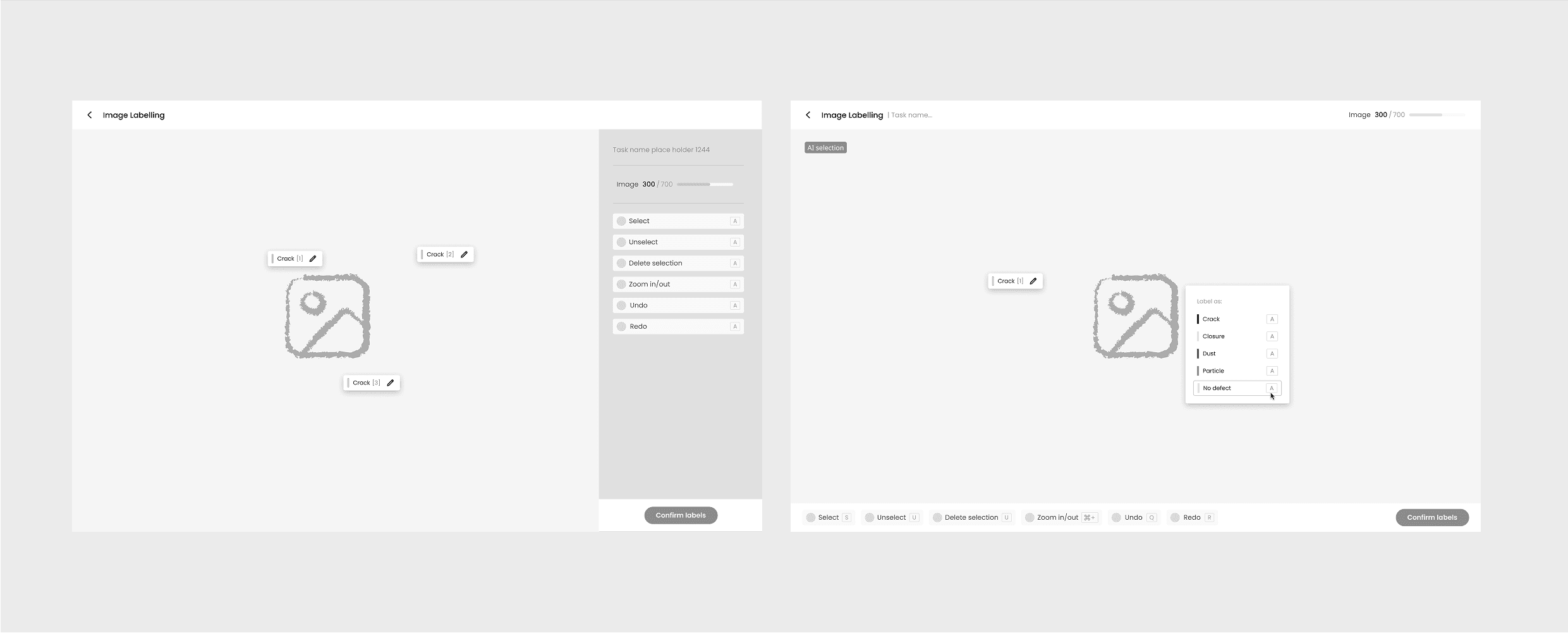

Iterations feedback

Iterations feedback

Iterations feedback

User pain points

❌ 1. Confusion between defects and selections

❌ 2. Marking "No Defect" per box was repetitive

❌ 3. No way to revise previous labels

Technical constraints

➔ 1. None

➔ 2. None

➔ 3. Limited to editing the last 3 images

Design solution

➔ 1. Applied distinct colors and overlays for clarity

➔ 2. Added a general "No Defect" button on footer

➔ 3. Added options to revisit and edit previous labels

1

1

2

2

3

3

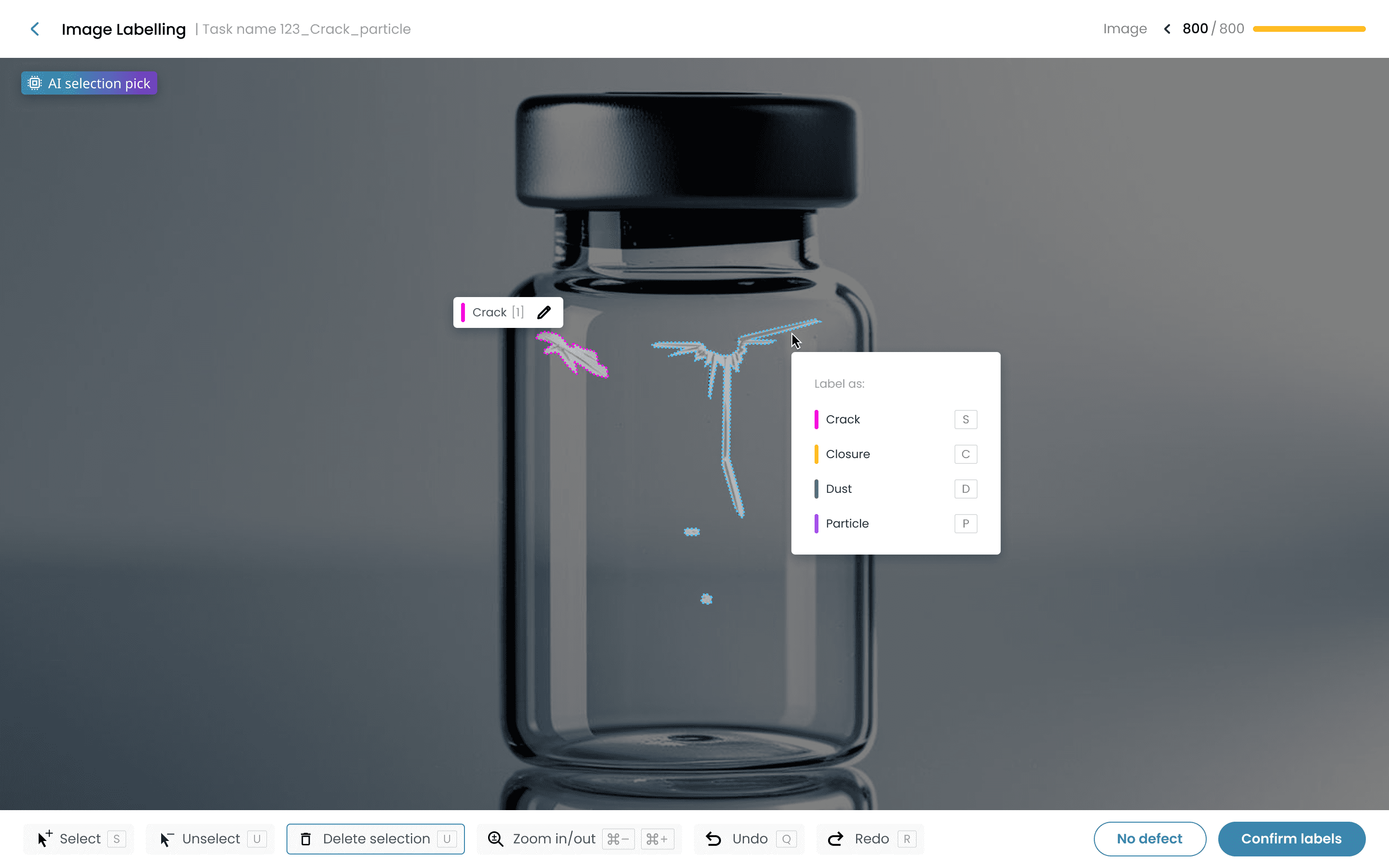

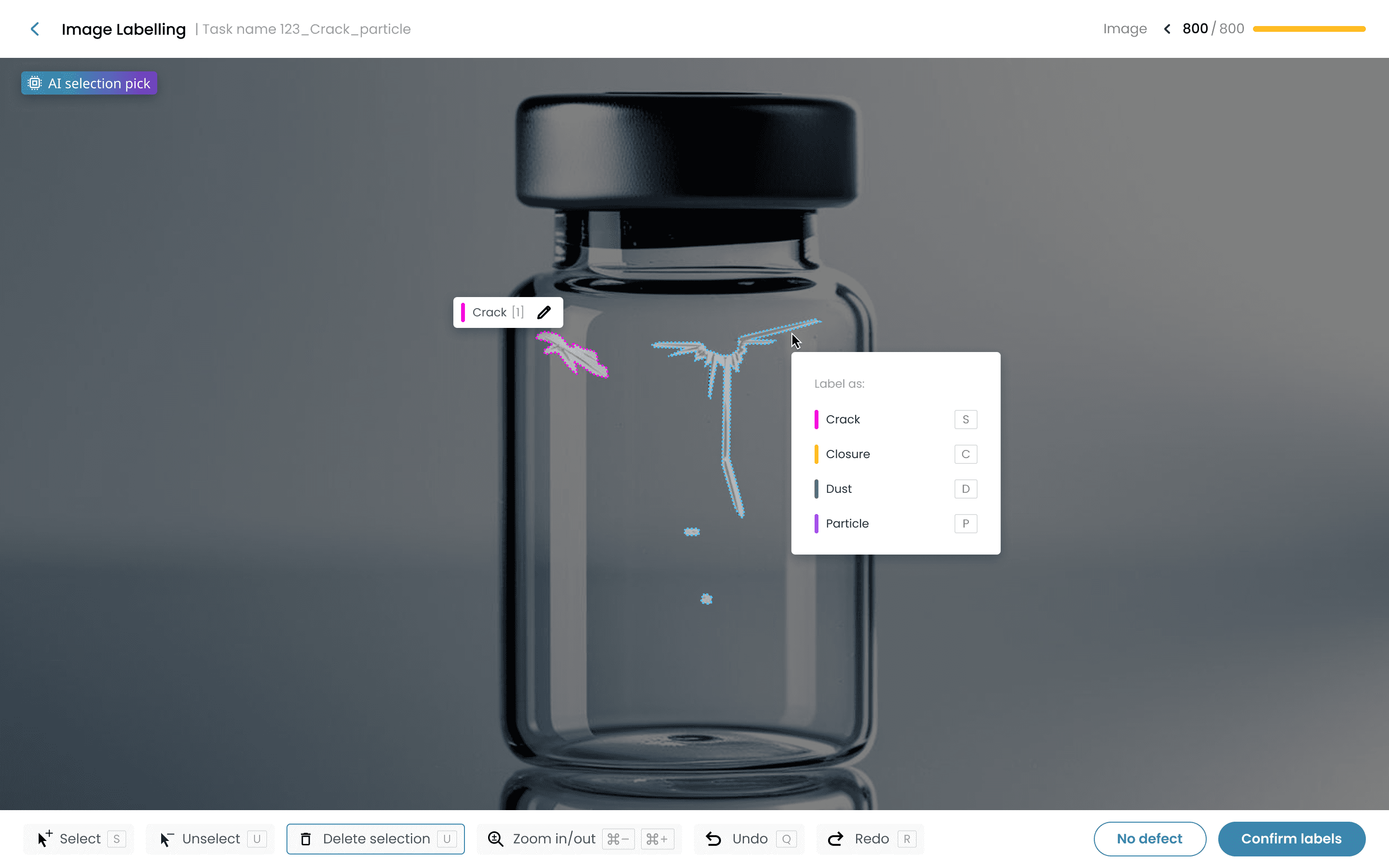

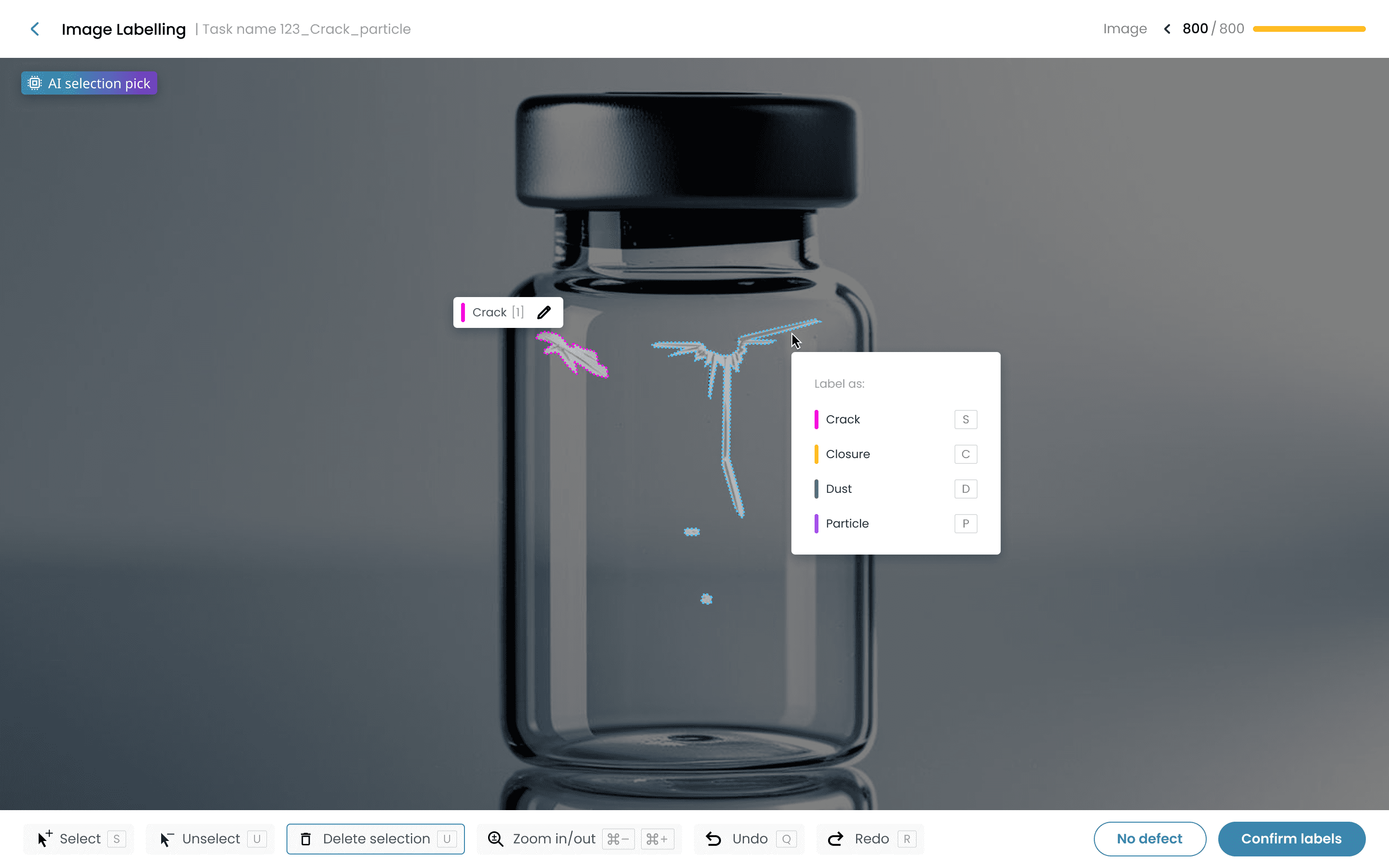

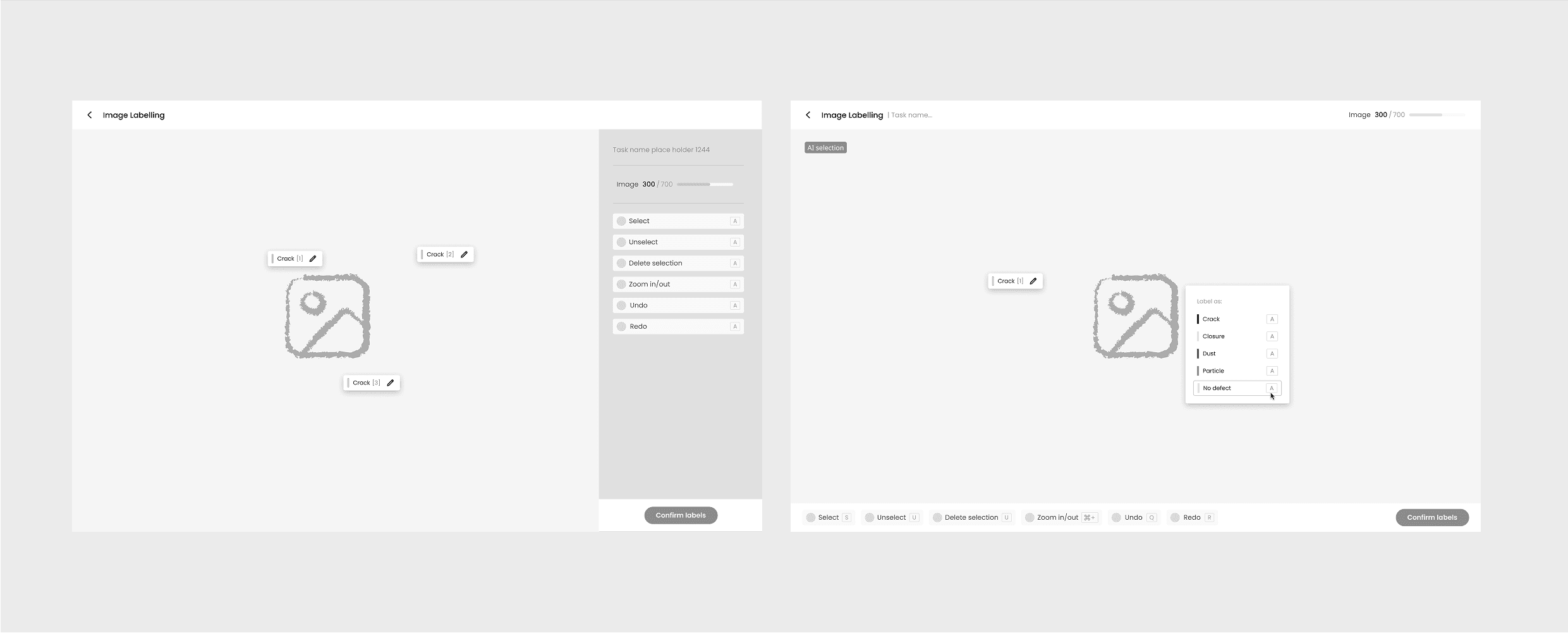

Final Design*

Final Design*

Final Design*

Design Principals Applied

Visibility & Feedback

Visibility & Feedback

Visibility & Feedback

Task progress indicator

Clear status indicators for defect detection

Task progress indicator

Clear status indicators for defect detection

Task progress indicator

Clear status indicators for defect detection

Accessibility & Equity

Accessibility & Equity

Accessibility & Equity

Efficiency & Workflow

Efficiency & Workflow

Efficiency & Workflow

Use shortcuts

Predictive inputs to improve speed.

Use shortcuts

Predictive inputs to improve speed.

Use shortcuts

Predictive inputs to improve speed.

*High-Fidelity Prototype (Labelling app)- Due to compliance and data protection policies, these visuals and data have been modified for showcasing purposes.

*High-Fidelity Prototype (Labelling app)- Due to compliance and data protection policies, these visuals and data have been modified for showcasing purposes.

5

5

5

5

Implementation

In this phase, I focused on documenting design specifications for developers and prioritizing features based on user needs, business goals, and technical feasibility. This ensured a clear handoff and alignment across the team for a smooth development process.

KPI's

KPI's

KPI's

99% Defect detection accuracy

99% Defect detection accuracy

99% Defect detection accuracy

The AI system now identifies nearly all defects, outperforming both manual inspections and previous machine systems.

The AI system now identifies nearly all defects, outperforming both manual inspections and previous machine systems.

The AI system now identifies nearly all defects, outperforming both manual inspections and previous machine systems.

75% Faster task completion

75% Faster task completion

75% Faster task completion

From 4 min to under 1 min per image labeling task after UI an AI improvements

From 4 min to under 1 min per image labeling task after UI an AI improvements

From 4 min to under 1 min per image labeling task after UI an AI improvements

100% User satisfaction

100% User satisfaction

100% User satisfaction

6/6 of labelers reported increased satisfaction with the new interface

6/6 of labelers reported increased satisfaction with the new interface

6/6 of labelers reported increased satisfaction with the new interface

key lessons

key lessons

key lessons

Reflection

Small usability improvements matter: Even minor interface enhancements can significantly boost accuracy, efficiency, and user satisfaction.

Iterative testing drives better outcomes: Regular feedback and multiple design iterations help uncover pain points early and refine the product.

Stakeholder alignment accelerates success: Ongoing communication with stakeholders ensures the solution meets both business and regulatory requirements.

Small usability improvements matter: Even minor interface enhancements can significantly boost accuracy, efficiency, and user satisfaction.

Iterative testing drives better outcomes: Regular feedback and multiple design iterations help uncover pain points early and refine the product.

Stakeholder alignment accelerates success: Ongoing communication with stakeholders ensures the solution meets both business and regulatory requirements.

Next steps

Leverage these learnings to design scalable, inclusive solutions for other high-compliance industries while continuing to prioritize sustainability and usability.

Leverage these learnings to design scalable, inclusive solutions for other high-compliance industries while continuing to prioritize sustainability and usability.

Leverage these learnings to design scalable, inclusive solutions for other high-compliance industries while continuing to prioritize sustainability and usability.

Portfolio

Other projects

Other projects

Other projects

Bite - Frozen meal

E-commerce ∙ Case study ∙ 2020

Photobooth redesign

Photobooth redesign

Photobooth redesign

Software ∙ Case Study ∙ 2020

Software ∙ Case Study ∙ 2020

Software ∙ Case Study ∙ 2020

AOP Punk Rock

E-commerce ∙ Events ∙ UI ∙ 2021

See all projects